Everything You Ever Wanted to Know About Low-Voltage Lighting

What is low-voltage lighting?

Low-voltage lighting refers to using lamps/bulbs which are not supplied with mains voltage (120V/230VAC), but which are supplied with a lower voltage, which may be either alternating current (AC) or direct current (DC)

Most typically, 12V is used for low voltage lighting. This was used to supply lamps of the MR16 or similar type

Why is low-voltage lighting used?

Low voltage lighting is used for a few reasons:

- Touch Safe – because the voltage is reduced, it is safe to touch the wiring. For example, overhead “string lights” like these can use exposed conductors to connect lamps without safety problems

- Higher efficiency – tungsten lamps run at reduced voltage are more efficient (although this is not true with LEDs)

- Point Sources – The low voltage allowed a short filament, meaning it was good for small point sources

How do we get from high voltage to low voltage?

To convert between voltages transformers are used. There are several different types of transformers:

Magnetic Transformers

Magnetic transformers have a long history dating back to Tesla’s initial work on AC electricity. They are simply two coils of wire around an iron core. The transformer converts the electrical energy to magnetism, and back to electricity at a lower voltage.

Magnetic transformers can be identified by:

- Size – generally bulky

- Weight – generally heavy

- Noise – tend to buzz in operation, especially if dimmed

- Voltage – operate on one input voltage only, or have multiple different wires for different input voltages

Electronic Transformers

Electronic transformers solve some of the problems of magnetic transformers by using electronic circuitry to convert high voltage to low voltage. They can be identified by:

- Size – relatively small

- Weight – lightweight

- Noise – quiet

- Voltage – likely to be universal input voltage

What about LEDs?

Originally these systems were all designed around tungsten lamps, but some of those lamps are no longer easily available, leading to a desire to retrofit to LEDs. Often it may be desired to replace the lamps but leave the transformers in place because they are inaccessible or part of a fixture. This needs to be undertaken with caution, especially if the system includes dimming of any kind.

Unfortunately, LED technology when driven through a transformer, especially one not specifically designed to work with a particular lamp, will not dim as well as the original tungsten lamps

Do not expect to upgrade a low-voltage lighting system to LED and achieve the same performance level as the tungsten system, especially without changing transformers. If high performance is needed, consider changing complete fixtures or the system to something with direct control

If you do have to upgrade a system without changing the transformers, determine:

- What type of transformers are in use – electronic or magnetic?

- Are the transformers a type capable of dimming?

- What replacement lamps are to be used?

- Are the replacement lamps capable of dimming?

- What is the existing load of tungsten lamps on the system, and what will that change to after the upgrade?

Ideally, test the lamps in a small section of the system first to make sure performance is as desired.

Dimming System

If you are working in a system with dimming, or adding dimming to a system, you must take some very specific precautions:

Never use an electronic dimmer on a system with magnetic transformers

Dimmers broadly fall into two categories – Electronic (dimmers which use transistors to switch power on and off), and SCR-based dimmers (which use an SCR or Triac to perform the switching).

From ETC’s portfolio, electronic dimmers would include Sensor/Unison ELV modules and Foundry phase-adaptable dimmers.

SCR-based dimmers would include the Sensor/Unison D20 module and the Foundry MLV Dimmer

When you switch power on and off to a magnetic device such as a transformer, as mentioned earlier the energy is converted into a magnetic field. When you turn off the power, the magnetic field collapses, and is turned back into electricity. This can lead to very high voltage spikes – these spikes can be enough to damage an electronic device such as an electronic dimmer, which works by turning the power on and off rapidly to dim the load.

Typical symptoms of that damage to an electronic dimmer are that the transistors are stuck on – the output never shuts off. A dimmer in this state has been physically damaged, and will need to be replaced.

Electronic dimmers generally have some level of fault protection in the dimmer, but in many cases the magnitude of the voltage spikes can be significant enough to cause permanent damage.

This problem gets even worse on transformers which are not loaded to their capacity. Transformers have a rating in VA (which can be treated the same as watts for our purposes here). So a transformer marked as 75VA would have supported 75W worth of tungsten lamps. When you switch those lamps out to LED lamps, the load goes down dramatically – which tends to make the problem of voltage spikes worse.

Be careful of transformer types

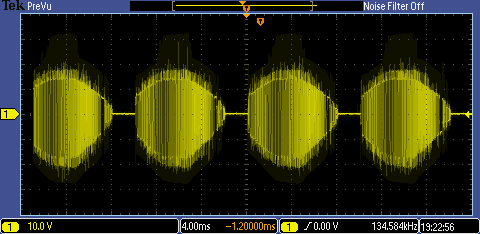

Even electronic transformers which were designed for tungsten lamps are not necessarily suitable for LED lamps. Some of them output a high-frequency chopped waveform which may cause damage to LED lamps:

Unfortunately, this can be difficult to determine without an oscilloscope. Again, testing a small section of the system with both the planned lamps and transformers is the only real way to guarantee against problems after upgrade.