Rise-Time: Facts and Myths

Equipment purchasers and specifiers are paying more and more attention to the RT 'number' in the spec. sheets and consequently manufacturers are encouraged to produce designs with ever higher rise-times. Some may think that a higher RT is an insurance policy against lamp noise in a system they are designing - and they may be disappointed.

So what is going on? - first a little about why dimmers buzz:

Since the 1960's practically all dimmers have been built using Thyristors or triacs. These devices operate like an on-off switch rapidly chopping up the mains waveform. Just as with movies or TV the human eye is not fast enough to see the lamp flashing on and off. The proportion of time on to time off is what determines the apparent brightness of the lamp.

The rapid switching current in a thyristor circuit gives rise to noise. There are several physical effects that cause acoustic noise. Firstly there is the thermal shock to the filament, caused by the rapid expansion of a heated metal. Another effect is the 'magneto-strictive' effect whereby a wire conducting current has a tendency to shrink or constrict. In a dimmer all this is happening at 100 times per second. Without some filtering the noise at the lamp would be intolerable - in addition the noise extends all they way to the radio spectrum and has to be filtered to meet the CE EMC standards.

The solution is the simplest electronic component of all - an inductor, more commonly known as a choke. This is no more than a wire wound round a (usually) iron core just like an electro magnet. The choke has a tendency to resist any rapid change in the current flowing through it. Modern dimmers use a whole range of choke designs, some very exotic, but they are all just the wire wrapped round a piece of metal.

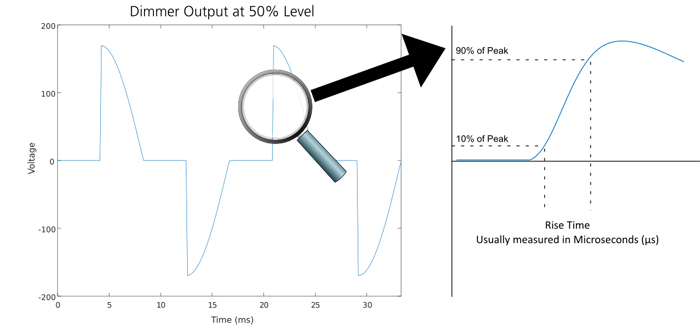

The worst case change of current occurs when the thyristor is turned on at the peak of the mains, half way through a half-cycle. This corresponds to exactly half power and 90 degrees through the mains sine-wave.

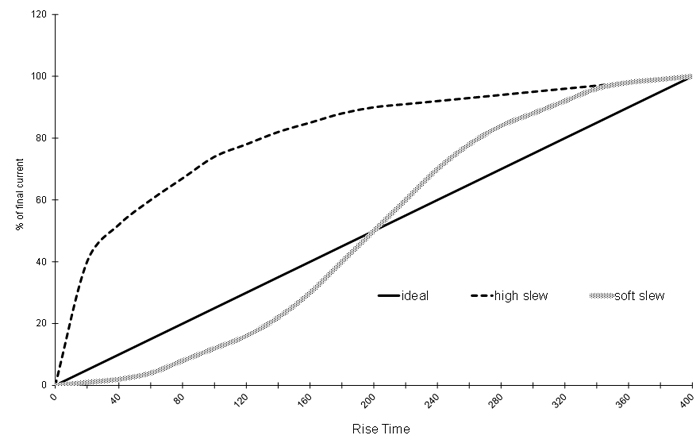

Rise-time is measured as the time it takes for the dimmer output to go from 10% to 90% of the full load current at this 90 degree point and is expressed in microseconds. The problem is that this just tells you how long it took to change, not what happened as it changed. Remember that the noise is caused by how fast the current rises. The ideal choke would rise at a constant rate from 0% all the way to 100%, however, a choke that rose from 10% to 89% almost instantly and then took all of the RT to reach 90% (an extreme example) would still satisfy the RT number and yet would be hopeless as a noise suppressor.

Real dimmers perform somewhere between these two extremes.

The RT is measured with the full load connected as this usually gives the best possible number for the spec. sheet, but is anyone telling you how this might changes at lower loads? Is anyone asking? The answer may be surprising to some - and again inconclusive. Low load RT can vary between a linear relationship, with zero load giving zero RT, half-load half RT and so on, in some designs to nearly full RT even at quite low loads in others. Again, actual noise performance may not relate directly to the RT - there is no hard and fast rule that makes higher RT better or worse than someone else's design, indeed there are some famous-name products that give very acceptable acoustic results and yet have surprisingly low RT's. There are also some designs that boast high RT and yield inferior performance due to the initial high slew-rate (SR) of the output current or suffer from nasty side effects such as voltage overshoot.

The slew-rate is the rate of change of current at the steepest point on the RT curve and is expressed in volts per second. The higher the slew-rate the more thermal and magnetic energy will get to the load and produce noise. So the ideal situation is high RT and low SR which can be difficult to achieve in practice.

These different approaches arise from the constraints placed on the dimmer designer. Chokes may be the simplest components but they are also by far the most bulky. Modern designs are getting ever smaller and there is no longer any room for the 'ideal' choke so the designer is faced with a dilemma - go for broke on the RT for the spec. sheet or try to build a genuinely quieter dimmer even if this means the RT number is not very 'good'.

Add to all this the fact that most of the weight, heat produced and volts lost in a dimmer are due to the choke and you can begin to see why it might be important to choose carefully the size you need.

Obviously the RT number is not really telling us what we all want to know; how much noise will I hear in the auditorium? The overall noise level will be affected by many factors; the dimmer itself, the lamp filaments, the construction of the lamp-housings, the wiring, acoustic resonance's in conduits and wire-ways etc. etc. What this industry needs is a simple method of measuring acoustic noise of at least some of these elements in a standard, repeatable way.

A simple method might be a reference lamp in an anechoic chamber to produce a noise number in decibels - the reference level might be with the choke removed from the circuit, the dB value would then give the attenuation offered by the dimmer. This idea needs development and input from industry bodies to determine, for instance, what is a reference lamp. Even if this proves to be difficult to agree on we could at least start to also specify the slew-rate in addition to the RT.